Steel Vapor Scrubber Systems

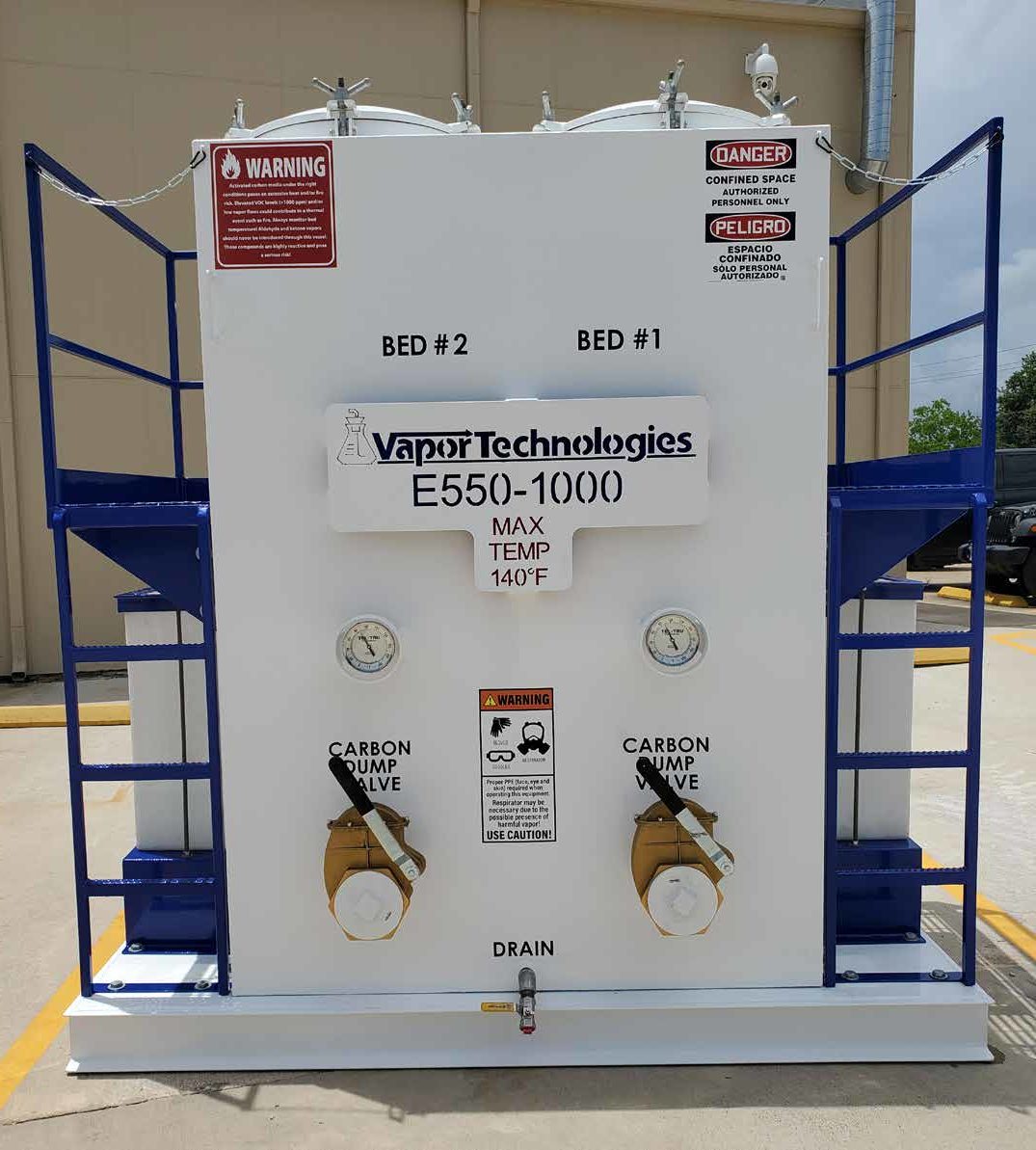

Eliminator E550-1000 Scrubber System

The E550-1000 is a skid mounted vapor control system comprised of a forced induction vapor scrubber followed by twin 1000# carbon beds. Designed for vapor flows up to 500 CFM. This system has a stainless steel E550 which alone can achieve 98% removal of vapor contaminants such as hydrocarbons. The twin 1000# carbon beds polish the vapors to near 100% removal. This system has temperature gauges and emergency water quench system which make it the safest system available today. Large carbon extraction valves make removal of spent carbon possible within 15-20 minutes. No carbon extraction machine or cyclone required! Catwalks included for both carbon bed which makes loading of fresh carbon safe and easy.

- Compact Design

- Liquid Scrubber Followed by Dual 1000# Carbon Vessels

- Designed for Vapor Flows Up to 500 CFM

- Excellent for Vacuum Truck Emissions

- Requires no Utilities!

- Includes One-Of-A-Kind Safety Features Such as Temperature Gauges as well as Emergency Water Purge System (in case of elevated temperatures)

- ‘Easy-Dump’ Carbon Valve Makes Removal of Spent Carbon Simple (Carbon Extraction Machine or Cyclone not Necessary)

| Unit Footprint | 92” W x 128” L |

| Unit Height | 8.2’ |

| Vapor Inlet Size | 4” |

| Vapor Outlet Size | 4” |

| Empty Weight | 6000# |

| Maximum Vapor Flow | 500 CFM |

| Utilities Needed | None |

| Maximum Pressure | 2 PSI |

| Pressure Drop Through Entire System | 40” of Water |

| Chemical Scrubber Volume | 275 gallons (Normal) - Maximum 400 gallons |

| Carbon Bed Volume | 1000# of GAC per Bed (2000# total per scrubbder unit) |

Related Products

Check out these other great Steel Vapor Scrubber Systems products

SST-20 Vapor Scrubber

Dual column stainless steel scrubber for vapor flows up to 750 CFM.

Eliminator 5500 Scrubber System

The Eliminator 5500 scrubber unit is designed to treat hydrocarbon and other vapors from Air-Movers and GapVac units which typically have exhaust streams around 5500 CFM.