Steel Vapor Scrubber Systems

SST40-N2K System

The SST40-N2K is a trailer-mounted system comprised of a dual stainless steel packed-bed liquid scrubber (SST-40) followed by a 2000# carbon polisher and a 1500 CFM blower. Excellent for remote jobs and projects. Applications include tank cleaning, vessel and line cleaning, tank degassing and more. Overall system efficiency as high as 99.999%. Available for sale or rent. Skid mounted versions available.

- Tank Cleaning Vapor Control

- Plate Press Vapor Control

- Centrifuge Vapor Control

- Pipeline Vapor Control

- Tank Degassing Vapor Control

- Any Many More!

| Overall Footprint | 8'W x 28'L (Trailer) |

| Maximum CFM | 1500 |

| Blower Rating | 1500 CFM @ 22" of water |

| Vapor Inlet #1 | 6"-150# Flange |

| Vapor Inlet #2 | 8" - 150# Flange |

| Vapor Outlet | 10" - 150# Flange (Scrubber or NOVAC Carbon Bed) |

| Carbon Bed | NOVAC 2000 |

| Pump#1 | Magnetic Drive Electric Pump (460V) |

| Pump#2 | AOD Air Operated Diaphragm Pump (1.5") |

| Maximum Flow Rate (CFM) | 1500 |

| MInimum Flow Rate (CFM) | 200 |

| Maximum Pressure (PSI) | 2 |

| Maximum Temperature (F) | 140 |

| Pressure Drop Across System with carbon (inches of water) @1500 CFM | 10 |

| Pressure Drop Across System without carbon (inches of water) @ 1500 CFM | Less than 3 |

Related Products

Check out these other great Steel Vapor Scrubber Systems products

Eliminator E550-1000 Scrubber System

The E550-1000 is a skid mounted vapor control system comprised of a forced induction vapor scrubber followed by twin 1000# carbon beds.

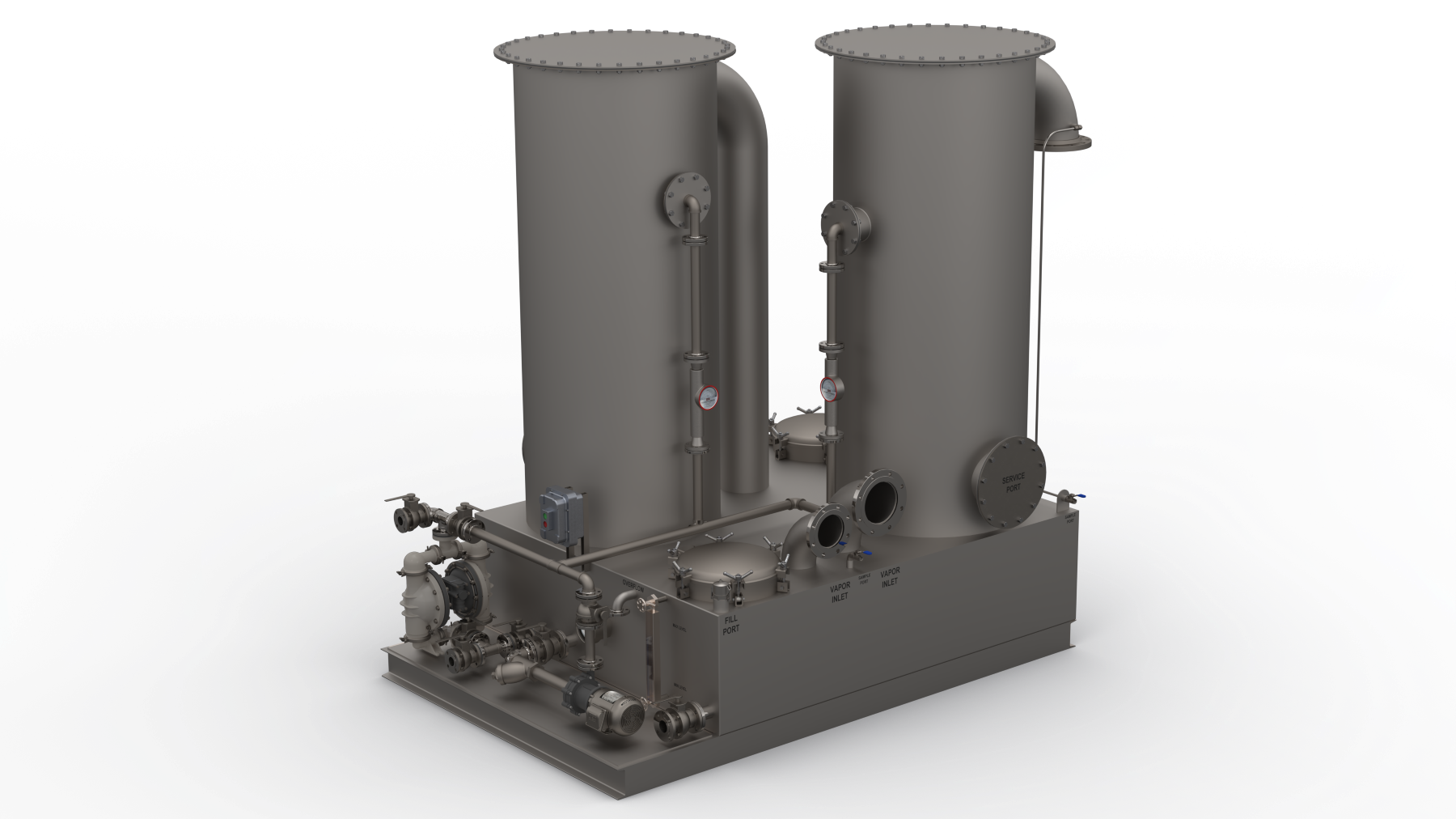

SST-40 Vapor Scrubber

The SST-40 Vapor Scrubber unit is a skid-mounted stainless steel, twin-column wet scrubber designed for vapor flows up to 3000 CFM.