Steel Vapor Scrubber Systems

Eliminator 550 Scrubber System

The Eliminator 550 is a 'forced induction' vapor scrubber unit. The main shell and internals of this unit are made from 304 stainless steel for corrosion resistance and longevity. These units use the force of the vapors through the unit to come in contact with our specialized stainless distributors which are located inside of the unit. The primary distributor creates a 360 degree pattern for the vapors to radiate out to the main distributor. The main distributor has enormous surface area yet provides almost no back-pressure inside of the unit. It is here where liquid-to-vapor cohesion takes place. This transfer zone yields extremely high removal efficiencies (high as 98%) for compounds such as hydrocarbons.

- Removal efficiencies as high as 98.5% for hydrocarbons such as gasoline!

- Uses Vapor Tech’s economically priced Bio Scrub X chemical media to absorb hydrocarbons.

- Excellent for vacuum truck emissions & tank venting operations.

- Includes check valve, sample ports.

- Requires no utilities!

- Excellent for remote locations.

- Using other scrubbing solutions, unit able to scrub a host of other vapors.

| Unit Footprint | 5.5’ x 6.5’’ |

| Unit Height | 9’ |

| Vapor Inlet Size & Type | 4” Flange |

| Vapor Outlet Size & Type | 4” Flange |

| Typical Chemical Volume | 275 gal (normal) / 400 gal (max) |

| Maximum Airflow | 550 CFM |

| Maximum Pressure | 2 PSI |

| Maximum Vacuum | 50” of W.C. |

| Sample Ports | One per suction and discharge (vapor) |

| Utilities Required | None |

| Pressure Drop Across Unit | 1.3 PSI (36” of water) at 450 CFM |

| VAPOR | RECOMMENDED CHEMICAL COUNTERACTANT |

| Hydrocarbons | Bio-Scrub X |

| H2S | Enviro-Scrub VT |

| H2S and Hydrocarbons | BSX50-EVT6 |

| Phenol | EZ-STRIP SS |

| Vinyl Acetate | VAMSOL 40 |

Related Products

Check out these other great Steel Vapor Scrubber Systems products

SST-40 Vapor Scrubber

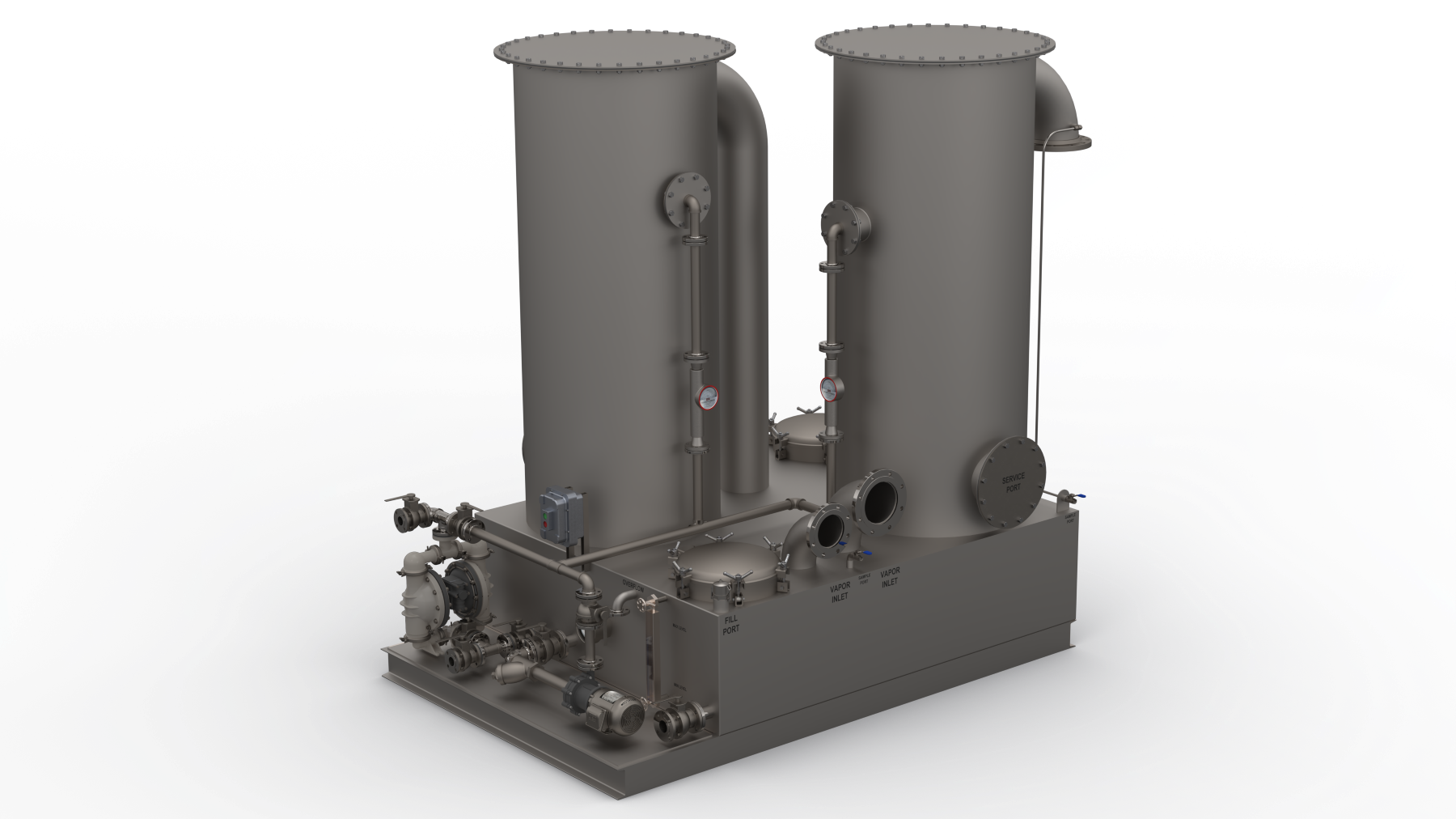

The SST-40 Vapor Scrubber unit is a skid-mounted stainless steel, twin-column wet scrubber designed for vapor flows up to 3000 CFM.

Eliminator 5500 Scrubber System

The Eliminator 5500 scrubber unit is designed to treat hydrocarbon and other vapors from Air-Movers and GapVac units which typically have exhaust streams around 5500 CFM.