Steel Vapor Scrubber Systems

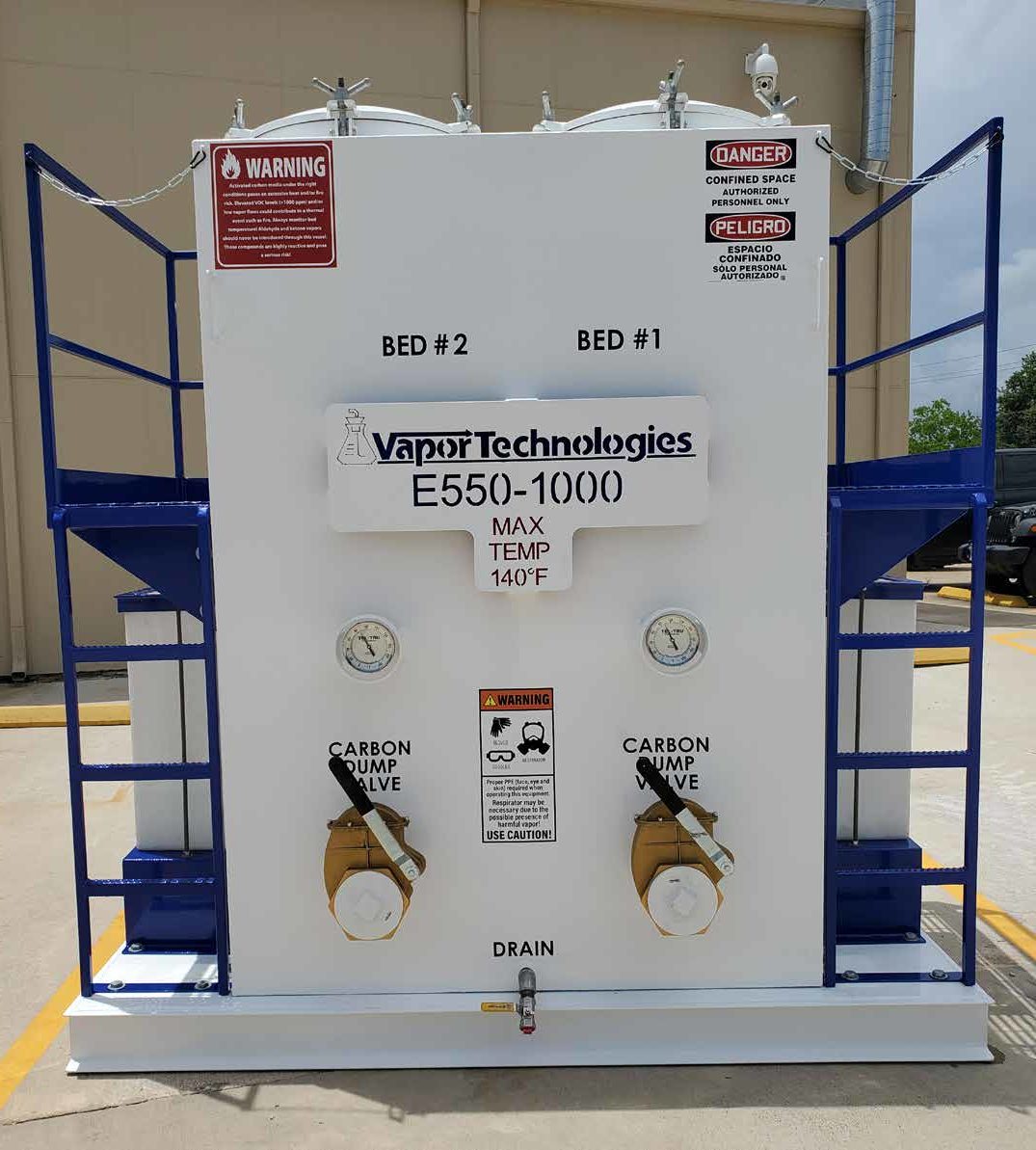

Eliminator E550-1000 Scrubber System

The E550-1000 is a skid mounted vapor control system comprised of a forced induction vapor scrubber followed by twin 1000# carbon beds. Designed for vapor flows up to 500 CFM. This system has a stainless steel E550 which alone can achieve 98% removal of vapor contaminants such as hydrocarbons. The twin 1000# carbon beds polish the vapors to near 100% removal. This system has temperature gauges and emergency water quench system which make it the safest system available today. Large carbon extraction valves make removal of spent carbon possible within 15-20 minutes. No carbon extraction machine or cyclone required! Catwalks included for both carbon bed which makes loading of fresh carbon safe and easy.

- Compact Design

- Liquid Scrubber Followed by Dual 1000# Carbon Vessels

- Designed for Vapor Flows Up to 500 CFM

- Excellent for Vacuum Truck Emissions

- Requires no Utilities!

- Includes One-Of-A-Kind Safety Features Such as Temperature Gauges as well as Emergency Water Purge System (in case of elevated temperatures)

- ‘Easy-Dump’ Carbon Valve Makes Removal of Spent Carbon Simple (Carbon Extraction Machine or Cyclone not Necessary)

| Unit Footprint | 92” W x 128” L |

| Unit Height | 8.2’ |

| Vapor Inlet Size | 4” |

| Vapor Outlet Size | 4” |

| Empty Weight | 6000# |

| Maximum Vapor Flow | 500 CFM |

| Utilities Needed | None |

| Maximum Pressure | 2 PSI |

| Pressure Drop Through Entire System | 40” of Water |

| Chemical Scrubber Volume | 275 gallons (Normal) - Maximum 400 gallons |

| Carbon Bed Volume | 1000# of GAC per Bed (2000# total per scrubbder unit) |

Related Products

Check out these other great Steel Vapor Scrubber Systems products

SST40-N2K System

The SST40-N2K is a trailer-mounted system comprised of a dual stainless steel packed-bed liquid scrubber (SST-40) followed by a 2000# carbon polisher and a 1500 CFM blower.

E6500-R3K High Volume Scrubber

Trailer mounted wet scrubber followed by twin 3000# Radial Carbon Beds.